We are responsible for more safe certifications all around the world then any other company. Based on our R&D and Designs, hundreds of safes and vaults, barrier materials, filling materials, mechanisms, electronic and electro-mechanical components were tested at various certification institutes and universities around the world and if required also certified under different norms like VdS, UL, CNPP, A+, SBSC, SSF..just to name a few.

Our ATM designs and constructions are used by most of the biggest ATM manufacturers. From Ultra light weight up to the highest rated ATM which is even explosive and core drilling resistant.

Same goes for the highest ever tested AND certified free standing safe under european CEN norms (euro grade 7), which is at the same time CD resistant and the highest ever tested and certified safe by Vds laboratories in Germany.

We are also the designers of a unique euro grade 7 ATM CD-EX (EX (explosive) and CD (core drilling) resistant), which was successfully tested and later manufactured in a small series of 50 pieces for a customer in the arab emirates. (It was self insured under risk management by a major underwriter).

And on top of that, even a grade 8 HS-Safe which was successful tested at the laboratories and later produced without certification in a limited series of 100 pieces for an important client in the jewelry trade in asia and the emirates.

Our ATM designs and constructions are used by most of the biggest ATM manufacturers. From Ultra light weight up to the highest rated ATM which is even explosive and core drilling resistant.

Same goes for the highest ever tested AND certified free standing safe under european CEN norms (euro grade 7), which is at the same time CD resistant and the highest ever tested and certified safe by Vds laboratories in Germany.

We are also the designers of a unique euro grade 7 ATM CD-EX (EX (explosive) and CD (core drilling) resistant), which was successfully tested and later manufactured in a small series of 50 pieces for a customer in the arab emirates. (It was self insured under risk management by a major underwriter).

And on top of that, even a grade 8 HS-Safe which was successful tested at the laboratories and later produced without certification in a limited series of 100 pieces for an important client in the jewelry trade in asia and the emirates.

A rough list of our achievements, designs and innovative technology in the industry over the last 17 years reads as follows :

1. implementations of internationally recognized Iso 9001/2000 standards for various clients, including QM handbooks, work and procedure instructions, in safe, vault, bolt work and lock manufacturing facilities on 3 continents, including recognition and acceptance at testing laboratories in Europe as a pre requirement for certification based physical testings.

2. dozens of different UHPC (Ultra High Performance Concrete) mixtures, w/w.o. nano technology, even reaching and surpassing density levels of 400 N/mm2, and procedures to reduce the level of rest water in the mixture with help of a chemical reaction !

3. synthetic 3 component mixtures for safes and vault panels, by saving 30% weight compared to concrete, without any kind of reinforcement, and the implementation of it at 2 production lines in Europe.

4. implementation of modular safe designs in various classes and standardization of parts to reduce costs for testing and manufacturing

5. bio chemical coating of electronic components in ATMs and electronic safe locks, to control life spams of certain critical parts, by taking environment protective measures into account

6. achieving euro grade 4 and 5 with panels of just 25mm thickness (less then 1 inch), for a particular ATM model and manufacturer in europe

7. achieving the highest ever tested and certified CEN grade for free standing safes and ATMs

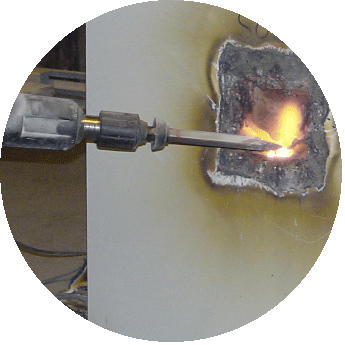

8. Core drilling and explosive resistent safe and vault constructions

9. several new bolt work designs, improvement of existing designs and implementation of the necessary overworked production methods in modern manufacturing

10. springless and cable less bolt works and mechanical active relocking without lock connections, incl. emergency unlocking

11. own lock design which is now used and certified as a gov.lock of one country in asia incl. their embassies all around the world

12. some of the biggest vault rooms ever built, both in massive and modular constructions, with up to 65 thousand SD boxes !

13. hydraulic operated remotely controlled vault doors, with and without self aligning hydro hinge design

14. hydraulic operated day gates for vaults with 40mm thick massive steel/concrete teethed panels for a customer in china

15. motor driven automatic bolt works

16. 24 hour drive in auto-deposit safe

17. new installation rail tracks with quick fixtures, for high volume safe deposit nest installment in vault rooms

18. nano particle research and mixing with fixed mixtures to close micro gaps in UHPC cement and partly/total replacement of micro silica

19. new high frequency vibration table to achieve the same amount of frequency at all points of the table when filling cement in safes and vault panels, preventing circular motion of mixtures in panels and the prevention of air holes in walls

20. production of metal foams in open and closed structures, ceramic filled metal foams, foaming of carbide, and vacuum sintering of carbide with various metal powders and gases

21. thermal lance resisting designs and materials

22. various new types of hard plates to protect certain security relevant areas of a safe or vault, incl ball bearing plates with carbide inserts by reducing carbon consistency and matrix bondage

23. various design improvements on ATMs to reduce material costs and labour by using different materials and production methods

25. network management of vault doors and SD boxes and full automative access to SD boxes

26. new self lubricating hinge designs for free standing safes and ATM’s with hidden cable channels

27. 2 central bank vaults in west africa and 1 bullion vault in south africa in massive construction built on existing grade 13 euro norms

28. based on our modular constructions, more then 250 vault rooms have been built in the last 6 years in asia alone. 3 of them drive in vaults where a complete armor car can drive in the room with interlocking gates. 1 double floor room and one with nearly 65.000 SD boxes with 12 vault doors.

29. new improved heat curves in sintering processes of concrete drying in computer controlled ovens, and heat sensors which guaranty the same amount of heat in all parts of the oven

30. vacuum sintering of various metal combinations and a new improved cool down process, reducing the time by 50% without the reduction of quality

31. ventilation channel systems in vault rooms

32. various cash withdrawal and deposit mechanisms in ATMs

33. new types of recycler ATMs

based on these accomplishments, achievements and many more research and testing results, most were implemented by various safe, vault, lock and mechanism manufacturers and up to this day produced and used all around the world in safes, vaults, vault doors, ATM’s, access control systems and quality management systems.

They also help Underwriters, risk controllers, loss adjusters, research institutes, government agencies and ministries, to have a better, deeper and more detailed understanding about certain aspects of safes & vaults and some of their specific components.

Have a look in my Design and Project Management section, to see how some of it looks like in real life…..

I currently work on the research of carbon fibers and nano particles in a join venture project with a material research devision at an university in south east asia…

Igor Matanovic

“Our lives are defined by opportunities, even the ones we miss “

1. implementations of internationally recognized Iso 9001/2000 standards for various clients, including QM handbooks, work and procedure instructions, in safe, vault, bolt work and lock manufacturing facilities on 3 continents, including recognition and acceptance at testing laboratories in Europe as a pre requirement for certification based physical testings.

2. dozens of different UHPC (Ultra High Performance Concrete) mixtures, w/w.o. nano technology, even reaching and surpassing density levels of 400 N/mm2, and procedures to reduce the level of rest water in the mixture with help of a chemical reaction !

3. synthetic 3 component mixtures for safes and vault panels, by saving 30% weight compared to concrete, without any kind of reinforcement, and the implementation of it at 2 production lines in Europe.

4. implementation of modular safe designs in various classes and standardization of parts to reduce costs for testing and manufacturing

5. bio chemical coating of electronic components in ATMs and electronic safe locks, to control life spams of certain critical parts, by taking environment protective measures into account

6. achieving euro grade 4 and 5 with panels of just 25mm thickness (less then 1 inch), for a particular ATM model and manufacturer in europe

7. achieving the highest ever tested and certified CEN grade for free standing safes and ATMs

8. Core drilling and explosive resistent safe and vault constructions

9. several new bolt work designs, improvement of existing designs and implementation of the necessary overworked production methods in modern manufacturing

10. springless and cable less bolt works and mechanical active relocking without lock connections, incl. emergency unlocking

11. own lock design which is now used and certified as a gov.lock of one country in asia incl. their embassies all around the world

12. some of the biggest vault rooms ever built, both in massive and modular constructions, with up to 65 thousand SD boxes !

13. hydraulic operated remotely controlled vault doors, with and without self aligning hydro hinge design

14. hydraulic operated day gates for vaults with 40mm thick massive steel/concrete teethed panels for a customer in china

15. motor driven automatic bolt works

16. 24 hour drive in auto-deposit safe

17. new installation rail tracks with quick fixtures, for high volume safe deposit nest installment in vault rooms

18. nano particle research and mixing with fixed mixtures to close micro gaps in UHPC cement and partly/total replacement of micro silica

19. new high frequency vibration table to achieve the same amount of frequency at all points of the table when filling cement in safes and vault panels, preventing circular motion of mixtures in panels and the prevention of air holes in walls

20. production of metal foams in open and closed structures, ceramic filled metal foams, foaming of carbide, and vacuum sintering of carbide with various metal powders and gases

21. thermal lance resisting designs and materials

22. various new types of hard plates to protect certain security relevant areas of a safe or vault, incl ball bearing plates with carbide inserts by reducing carbon consistency and matrix bondage

23. various design improvements on ATMs to reduce material costs and labour by using different materials and production methods

25. network management of vault doors and SD boxes and full automative access to SD boxes

26. new self lubricating hinge designs for free standing safes and ATM’s with hidden cable channels

27. 2 central bank vaults in west africa and 1 bullion vault in south africa in massive construction built on existing grade 13 euro norms

28. based on our modular constructions, more then 250 vault rooms have been built in the last 6 years in asia alone. 3 of them drive in vaults where a complete armor car can drive in the room with interlocking gates. 1 double floor room and one with nearly 65.000 SD boxes with 12 vault doors.

29. new improved heat curves in sintering processes of concrete drying in computer controlled ovens, and heat sensors which guaranty the same amount of heat in all parts of the oven

30. vacuum sintering of various metal combinations and a new improved cool down process, reducing the time by 50% without the reduction of quality

31. ventilation channel systems in vault rooms

32. various cash withdrawal and deposit mechanisms in ATMs

33. new types of recycler ATMs

based on these accomplishments, achievements and many more research and testing results, most were implemented by various safe, vault, lock and mechanism manufacturers and up to this day produced and used all around the world in safes, vaults, vault doors, ATM’s, access control systems and quality management systems.

They also help Underwriters, risk controllers, loss adjusters, research institutes, government agencies and ministries, to have a better, deeper and more detailed understanding about certain aspects of safes & vaults and some of their specific components.

Have a look in my Design and Project Management section, to see how some of it looks like in real life…..

I currently work on the research of carbon fibers and nano particles in a join venture project with a material research devision at an university in south east asia…

Igor Matanovic

“Our lives are defined by opportunities, even the ones we miss “